- Investigate the occurrence pattern of the issue. Check if the issue commonly happens after the camera is powered on or if it occurs some time after starting up. Examine the error messages in the camera logs and check Log Entries to determine if the camera has experienced any abnormal restarts.

- Disconnect all relevant devices to eliminate interference. If the issue does not reoccur, it is likely to be a site interference issue. If the issue persists, it indicates a hardware problem that requires returning the camera to the manufacturer for repair.

- If the issue is determined to be a site interference one and further experimentation is needed on-site, verify whether the interference originates from the power supply or the camera itself.

- If the interference is determined to be coming from the camera itself, add an insulated bracket. If it is determined to be power supply interference, add a surge protector. In more demanding environments, it may also be necessary to add an online UPS (Uninterruptible Power Supply) for additional protection.

EMI for cameras

Industrial cameras usually operate in production workshops, which are known for their harsh environments. In these workshops, various equipment like conveyor belts and industrial robots can potentially interfere with the normal functioning of cameras. Generally, three main issues arise in the workshop environment:

- Surges and EFT (Electrical Fast Transient) interference are caused by frequent startups of transformers, motors, and other equipment, resulting in chaotic oscillations in electrical power systems.

- The starting and stopping processes of motors, transformers, and capacitors generate radiation that interferes with sensitive sensors.

- In motion, industrial equipment in dry workshop environments tends to accumulate a large amount of charge. This charge can lead to air discharge or contact discharge, both of which are types of electrostatic discharge (ESD) and pose a risk of damaging sensitive components.

Industrial cameras, as image sensors, operate in low-voltage environments and are particularly sensitive to ESD, EFT, and surges. This post specifies methods for identifying and addressing interference in these cameras’ working environments.

Possible sources of external interference:

- On-site radiation from electric motors, transformers, capacitors, etc.

- The power source.

- Signal cables.

- A disorganized grounding system.

Phenomena that occur when the camera is affected by EMI:

- Missing depth maps.

- Missing 2D images.

- Dropped frames.

- The fluctuation in the camera’s image processing time.

- Camera instability.

Investigate EMI issues

Begin by checking if there are any heavy-current devices in the working environment, such as contactors, air circuit breakers, power supply devices, voltage conversion transformers, etc. Also, examine light-current devices like AC variable frequency drives, DC control devices, servo control devices, robot control modules, etc. The presence of any of these devices indicates on-site EMI, which can disrupt the camera’s normal operation.

-

Confirm the grounding status of the camera using the following methods. Note that either of the two grounding methods mentioned below should be met:

-

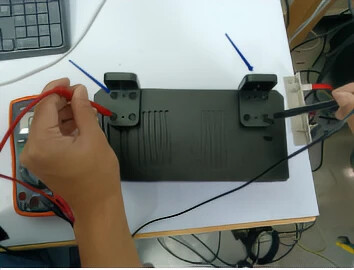

Test the power interface and network port to ensure they are both securely connected. Taking the Log S camera as an example, use a multimeter’s buzzer mode to test. If there is no sound, it indicates that the network port and power interface are not connected so it is necessary to remove the oxidation layer from them.

-

Verify if the installed adapter is securely connected. Taking the Log S camera as an example, test it using the buzzer mode of a multimeter. If no sound is heard, it indicates that both the adapter’s fixing bolts and the inner walls of the holes require polishing. See the blue arrows in the image below:

-

-

Check interference caused by ground conduction in the production workshop

Whether the camera is mounted on the truss or on the robot arm, it is connected to the production workshop’s ground by the camera strap lug. To address this issue, replace the camera strap lug with an insulating one. After the robot stops working and the camera is removed, conduct a static test to observe if the interference weakens. -

Address power supply noise interference in the production workshop

Distribution cabinets supply power to numerous pieces of equipment in the production workshop. When the factory starts or stops equipment operations (or switches between inductive and capacitive loads), it causes fluctuations in the bus voltage and pulse noise. Power electronic devices like variable frequency drives, inverters, and VAR compensators can introduce harmonic pollution to the power grid. It is recommended to use a separate UPS to power the camera and observe whether the interference weakens. Traditionally, surge protectors and voltage stabilizers are used for verification. If verification measures are taken, an online UPS can be directly used.

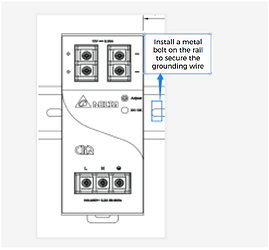

Notes on installing grounding wire:**-

If the rail is connected to the distribution cabinet’s metal casing, both should be grounded. Additionally, you can install a metal bolt on the rail to secure the grounding wire.

-

If the rail is neither connected to the distribution cabinet’s metal casing nor grounded, you can fix the shielding wire of the DC power supply cable and the protective grounding wire of the AC power supply cable at the same point.

-

If there are only live wire and neutral wire, and no grounding wire is provided, please contact the on-site engineer for assistance.

-

-

Check interference from the robot arm

After dismounting the camera, move it at least 2 meters away from the robot and observe its operational status. If the interference disappears or diminishes, it can be concluded that the robot arm is the source of the interference. However, when working at a customer’s site, the robot arm cannot be altered. To reduce the interference caused by the robot arm, use shielding fabric to cover the network cable. Additionally, keep in mind two points: firstly, ensure that the shielding fabric tightly wraps around the cable, and secondly, the shielding fabric should be grounded. -

Check interference caused by instantaneous startups of certain devices

The camera’s working site may have other heavy and large equipment that interferes with the power grid during their startups. If the camera occasionally experiences power outages and the surge protection box functions ineffectively, an online UPS can be used to determine if startups of other devices are interfering with the power grid. -

Check if the router/switch is interfered with

In general, routers and switches used in industrial environments lack adequate anti-interference capabilities, leading to unstable image transmission. In such cases, it is recommended to use industrial routers or switches. If the camera can be directly connected to a PC by network cables, additional routers/switches can be used to verify if the image transmission is interfered with.

It is advisable to use industrial routers or switches in the production workshop. The image below shows a TL-R483G industrial 5-port Gigabit router, and the grounding configuration of it is illustrated in this image:

-

Check if the network cable is interfered with by spatial coupling, including coupling interference between cables like power cables and network cables

In industrial environments, cable arrangements can be complex, often with multiple cables such as power cables and robot power cables coming into contact or being bundled together. This increases the likelihood of coupling interference between these cables. To address this issue, it is necessary to either ensure that the network cable is equipped with a shielding layer or use conductive fabric as the grounded shield, as shown in the image below:

-

Check if the industrial personal computer (IPC) is interfered with

The likelihood of interfered with IPCs affecting image transmission is very low. If the IPC is interfered with, snowflake patterns will appear on the monitor. In such a situation, verify the issue by either connecting the IPC’s power supply to an online UPS or grounding the IPC.

Summary

| Causes of interference | Troubleshooting methods | |

|---|---|---|

| 1 | Ground conduction in the production workshop | Replace the camera strap lug with an insulating one or remove the camera |

| 2 | Power supply noise interference in the production workshop | Use a separate UPS to power the camera |

| 3 | Coupling interference between cables | Move power cables and network cables away from other cables |

| 4 | Interference from the robot arm | Either turn off the robot, move the camera away, or use conductive fabric |

| 5 | Instantaneous startups of certain devices | Use a separate online UPS to power the camera |

| 6 | Interference with the router/switch | Use industrial routers or switches (grounded) |

| 7 | Network cable interference due to spatial coupling | Use conductive fabric as the grounded shield (no.3 and no.7 in this table are comparable) |

| 8 | Interference with IPC | Either connect the IPC’s power supply to an online UPS or ground the IPC |