Hello all,

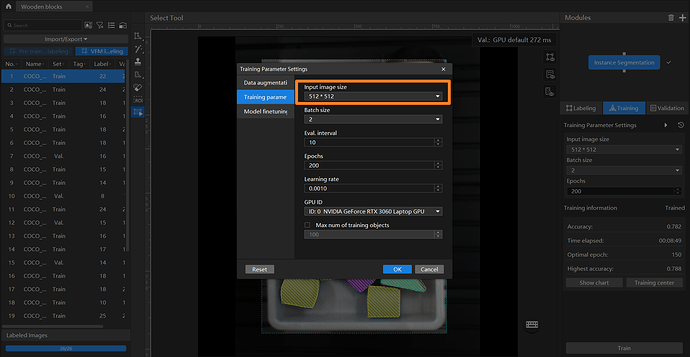

I am currently undertaking a project using Mech-Mind’s 3D vision system for robotic picking from a mixed pallet environment. The hardware is working well in my experience, but I am encountering some lag or time lost when running object detection. This is especially noticeable in mixed object pods, and with lighting changes and overlapping objects. I am using Mech-Eye LSR and Mech-Vision for my workflow.

My questions are: Is there a best practice - tuning the ROI or reworking the training data with increased variability to optimize for detection speed and reliability in such mixed object use case? Also, does a more powerful GPU greatly affect Mech-Vision processing time?

I came across this website:https://community.react-js-online-training-mech-mind.com/t/topic/356

I have read some documents in the Mech-Mind developer hub but I’m most interested in learning from people who have dealt with similar issues in real-life situations. Any practical tips or workflow changes that helped in your experience?

Thank you in advance - look forward to your opinions.

williamclark