Hello everyone… ![]()

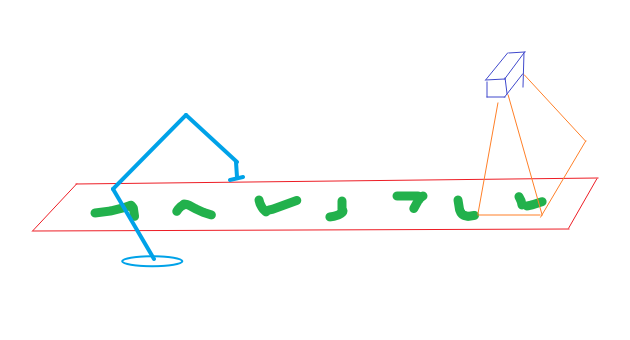

I am currently working on a project where I am trying to integrate Mech-Vision with a robotic arm to automate a pick-and-place task. The setup involves Mech-Eye 3D cameras, Mech-Vision for object detection and pose estimation, and Mech-Viz for motion planning. My end goal is to reliably pick up small objects (about 5-10 cm in size) from a conveyor belt and place them into designated bins based on color and shape.

Here’s where I am encountering challenges:

- Pose Accuracy Issues: While the camera detects the objects, the robotic arm sometimes misses the exact grasping position. The pose data in Mech-Vision seems accurate, but something may be going wrong during the handover to Mech-Viz. Could it be a calibration mismatch?

- Dynamic Objects on Conveyor: Objects move at a moderate speed on the conveyor belt. I’ve set up a trigger to capture images at specific intervals, but it doesn’t always align with the robot’s action. Is there a way to improve synchronization between the vision system and the conveyor?

- Error Handling: Occasionally, the robot fails to pick an object due to overlap or misdetection. I want to add a retry mechanism or a fallback workflow in Mech-Viz, but I’m not sure where to start.

I also check this: https://community.mech-mind.com/t/topicalteryx But I have not found any solution.

Thank you in advance for your help!

Respected community member!