I’m testing a small project using a 3D camera for seam tracking. Is there any solution for this project? Can you give me a sample to make this project?

Hello, could you give us more info:

- What type of seams specifically? (It would be helpful for us if you could provide image samples.)

- What 3D camera are you using?

- Any requirements on accuracy?

Thank you.

Hello, thank you for replying me

- I am using mech-mind camera model: PRO S.

- High precision is required because of its application for welding.

- Can you give me a sample about seam tracking in mech-vision?

Thank you for replying.

Could you describe the appearances of the seams?

Just to confirm: Are the seams straight indentation lines, or edges with ridges, or edges with beveling? Or irregular fissures? Or others?

Or is it simply a straight vacant line between two flat steel plates?

So that we can determine what the most suitable solution is.

Thank you for your patience.

Thank you for replying,

The connecting line is it simply a straight vacant line between two steel plates. Just detect the seam on the surface of the workpiece and send the robot to weld the seam.

My colleague is fetching the project template.

I’m really looking forward to your project samples. I’ll wait until

your colleague finishes. Thank you so much.

Hello, Have your colleagues found a project template or solution that

solves this problem?

Will send you today

Thank you so much

You can download the project here. Open it with 1.8.0 software.

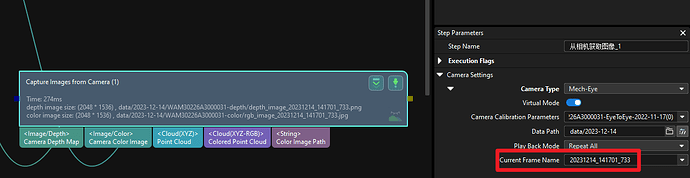

This project’s data includes multiple forms of welding seams. You can select data at this parameter below and run the project to see the effects.

For your “straight vacant line”, please select 733.

(You can ignore the Chinese Step names. Those names are already written on the Steps in English with the same meanings.)

The basic approach of the project is to find distinguishable features of one end of the seam, make a point cloud model, and use 3D matching to find the endpoint where the seam starts.

In this project, we only demonstrated the case of finding one end.

So for your application, because we have not obtained specific data from you, what we suggest is that you follow the same approach, i.e., finding the distinguishable and repetitively occurring features of seam ends, making a point cloud model, and using 3D matching to locate those ends, so that your robot will know where to start and where to stop.

If you need assistance in making the 3D point cloud model and tuning the parameters to make the project work on your image data, please contact our technical support for prompt help.

In your project, you only found 1 seam start. Currently, I can only find 1 starting point of the seam and I don’t know how to determine the 2 starting and ending points of the seam on the surface of the workpiece so that the robot can determine 2 poses and bring the robot to welding.

In other words, you can consider the seam ends the workpieces to recognize, and use 3D matching to recognize them. The things you should work on are to find the common features of the seam end shapes (this can consist of parts of the metal plates, and the long and narrow part of the working platform captured by the camera through the seam, as you can see in the demonstration project), and make a point cloud model out of them. For parameter adjustment for 3D matching Steps, you can seek prompt help from our technical support team based on your image data.