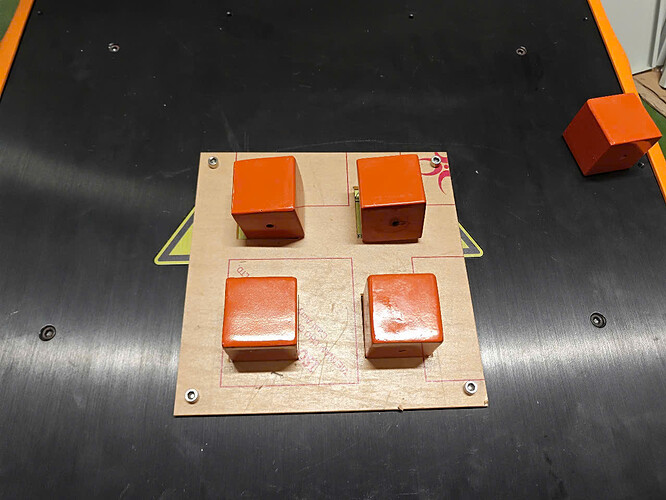

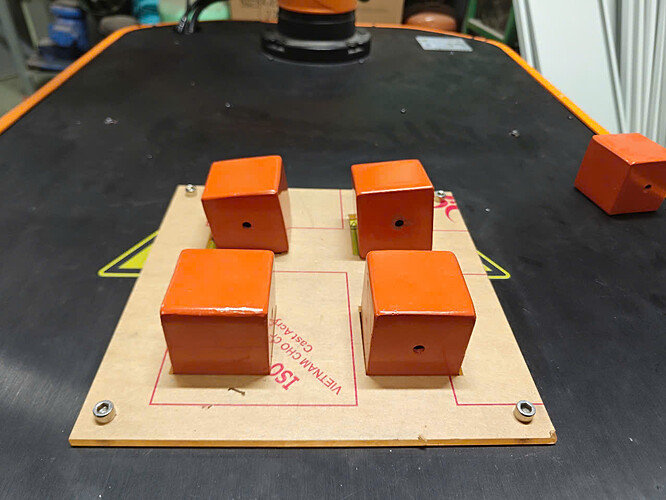

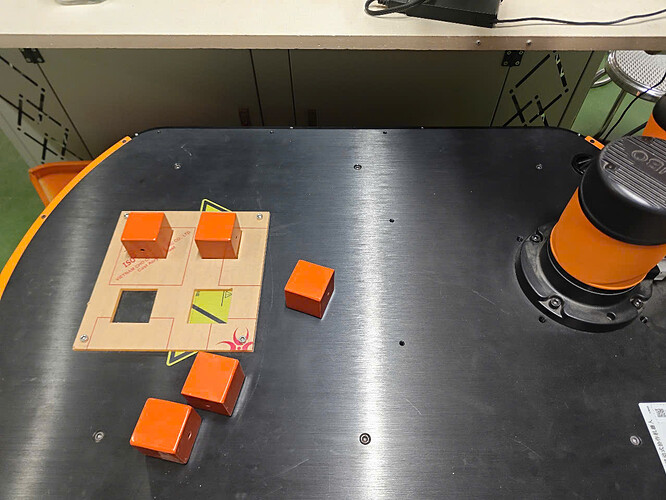

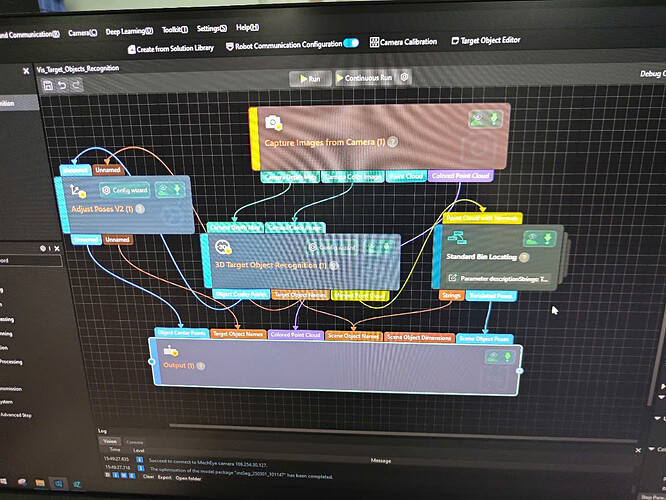

Hi everyone, I am working on the Aubo i5 project to pick up 50x50x50 (mm) blanks and place them on pallets. I use the “Palletizing” tool available on Viz software. I have configured the pallet size, placement point, number of blanks on a pallet,… But when placing them down, there will be 1 to 2 blanks that are out of position (1 to 3 millimeters). I hope you can help me.

HI, LongShao

Here are a few clues for you to check.

- You need to check if the tcp pick up the object within the wrong position.

- You need to check if your placement position matches your actual location.

- You need to check the accuracy of the robot.

Hi HaoChen. I understand what you mean. I summarize as follows:

+) Regarding problem 1: The position I placed is in the capture area of the mech eye. Is it necessary that: the position must match 100% with the position when using DLK scan?

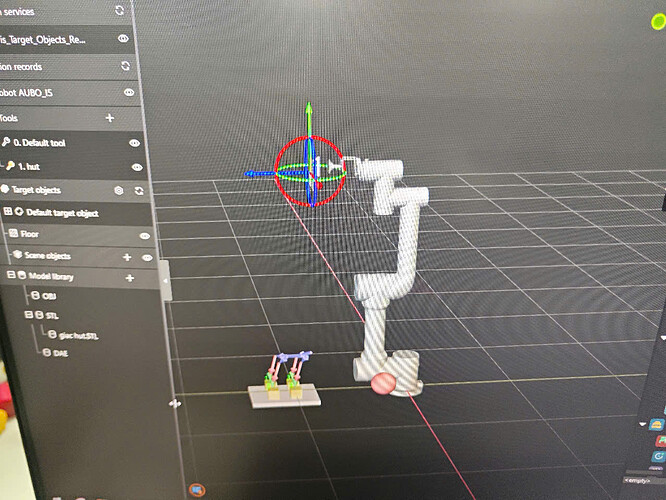

+) Regarding problem 2: I still keep the TCP pose as in the previous problems, no change, but my TCP accuracy is not very high as shown in the image below. I hope you can guide me to correct it

+) Regarding problem 3: I trust the accuracy of AuBo.

=> I am suspecting the clamp or I configured the pallet tool in VIZ incorrectly.

It’s too late now, I think you also need to rest. I’m still waiting for you tomorrow, I hope you respond

- No, The object pose can be obtained either through 3d matching or through deep learning.

- You could calibrate the tcp with calibration tool on robot teach pendant

One last question, Is your placement point obtained from vision capturing or from the palletizing step in Viz?

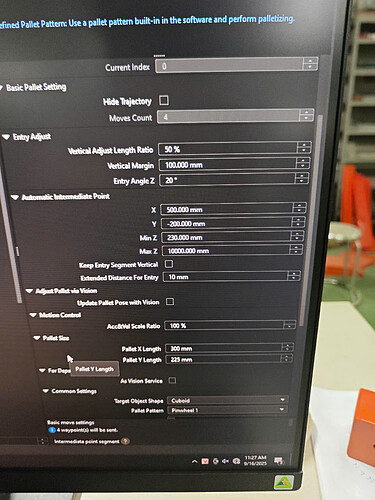

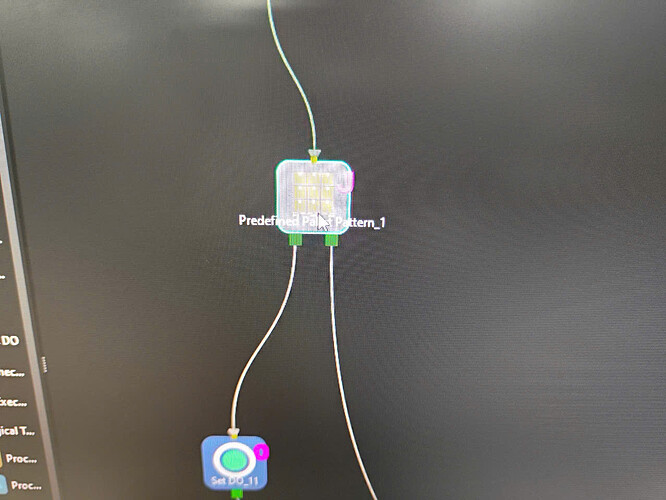

My blank placement point when the camera takes a picture is always within the placement area when I scan DLK. As for the pallet placement point, I rely on the “Predefined pallet pattern” tool for support.

I tried to adjust in “Predefined pallet pattern” but it didn’t work, maybe I adjusted it incorrectly, the situation is still the same. I still have all the pallet drawing files, 50x50x50 blanks, clamps. Please help me check via Ultra viewer

I understand that your placement point is provided by viz, which is a fixed position. What I mean is that you need to make sure this fixed position is consistent with the real position.

do you mean “pallet pose” on the software: x,y,z must match reality

yes

- yes, i got the problem. thank you. When pallet pose has X=0,Y=0,Z=0 then it will coincide with Robot origin. I will adjust it now.

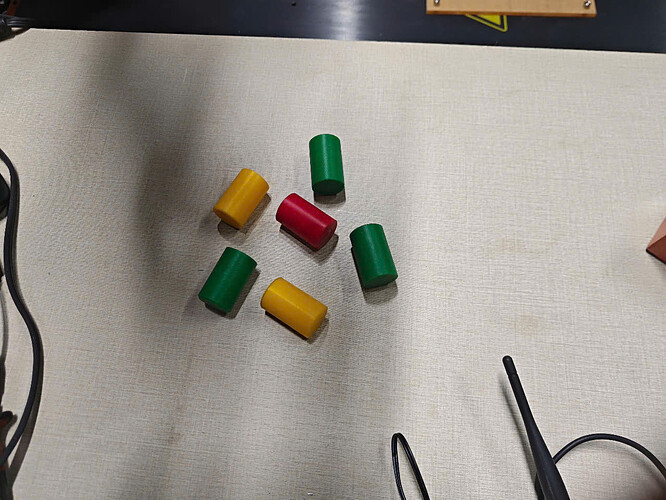

- There is one more problem in my next project in color classification, there is color as below. I want VIS to take a picture and VIZ will pick red color into red warehouse, yellow color into yellow warehouse, blue color into blue warehouse. I am having trouble in VIS and VIZ with the following situation: It picks up the correct color when I scan on DLK but it cannot put the correct color into classification warehouse. I am still online waiting for you, looking forward to your response.

Thanks

Please check whether the label of object is the correct color in vision, and check whether the robot run to correct branch(path) by label.

I tried to solve the problem your way but it didn’t work. It’s too difficult for me. I hope you can help me remotely. Through Utral View software or any software. I hope you can help me. I’m still waiting.