- Z Repeatability (σ)

Z-direction single-point repeatability (1σ): one standard deviation of 100 measurements of the single-pixel Z value; the measurement target is a ceramic plate, and the camera reaches a thermal equilibrium state during the measurement, taking pictures at intervals of 5s. Z-direction single-point repetition accuracy (1σ) is used to evaluate the accuracy of a single pixel point in the z-direction. For example, in the application of thin steel plate identification, it is necessary to distinguish two layers of steel plates through depth maps or point clouds, and the Z-direction single-point repeatability (1σ) should preferably be less than 1/6 of the thickness of the steel plate.

There are other names for this parameter, all of which have the same meaning:

point precision, Repeatability, Temporal noise

Z-direction area repeatability (1σ): One standard deviation of 100 measurements of the difference between the Z mean values of the two areas in the depth map; the measurement target is a ceramic plate. The area size is 200*200 pixels. Z-direction area repeatability (1σ) is used to evaluate the accuracy of the fitted plane in the z-direction. For example, if you already know the area of the depth map where the two planes are located (for example, the two plane areas in the corresponding depth map are given by 2D deep learning), evaluate the accuracy of the height difference between the two. If you need to rely on the depth map or point cloud to identify two planes, you need to refer to the Z-direction single-point repeatability (1σ).

Note: The repeatability index of Mech-Eye UHP-140 is the result after using filter processing; the repeatability index of other models is the result without filter processing.

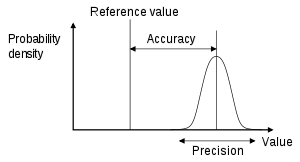

- Accuracy

Definition: The closeness of agreement between a measured value and a true value.

In order to avoid the interference of other factors, standard measuring tools with friendly shapes and materials are generally used for measurement, such as flat plates and bats. Mech-Mind is measured using a bat/dot calibration plate, and the center distance/center distance error is used as the accuracy. Based on the second part of VDI/VDE 2634 in the “Measurement Accuracy” index of UHP, the median of multiple pose error values is taken as the result.

There are other names for this parameter, all of which have the same meaning:

Measurement accuracy, Dimension Trueness