Hello Good Day!

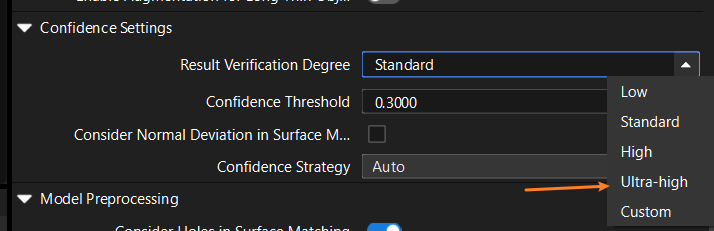

I would like to ask about how matching is scored? I am working on a pick and place project at present and due to the small gap of the tool and the work jig during picking, i have to improve the alignment of the matching result. One of the method that i was able to improve the alignment was to reduce the target object to a simpler shape. But with that method reduced the matching score and now i have to explain to the boss why it is more accurate yet lower in score.

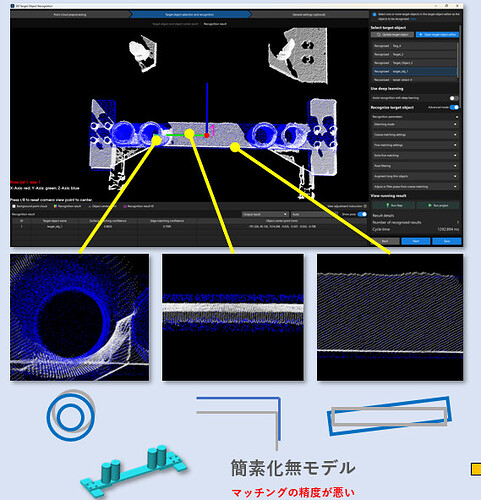

the original target object model is a 4 pipes extruded from an “I” shaped bar (in cyan lower left).

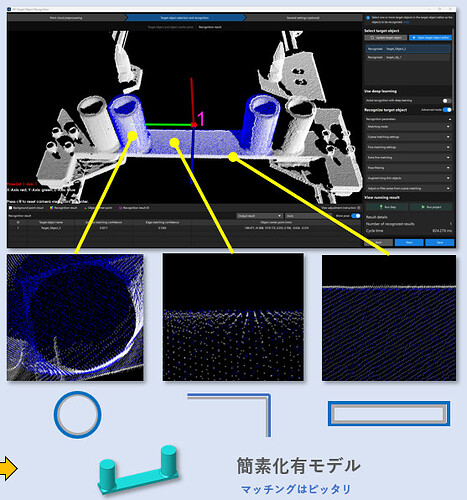

I remodeled it so that it will only have the middle 2 pipes and a section of the bar, filled the hole in the pipe and added chamfer to represent the shape of weld bead of the actual work.

The mis-alignment is exaggerated and represented by the simple shapes below the zoom-in of point clouds. The scores on the first model (mis-aligned) averages to 95% while the 2nd model (somewhat aligned) averages to 85%. How did this happen? or can you recommend an article that i should read to enlighten my self?

Your answer will be much appreciated! Thank You!