Introduction

Target Reader: Solution Engineers, Layout Planning Engineers, Mechanical Design Engineers, Mechanism Design Engineers, etc.

Post Overview: This post focuses on loading neatly arranged rings. It elaborates in detail on common challenges encountered in the industry, such as incoming materials for rings, picking, and corresponding solutions to address these challenges. This information provides significant guidance for the overall design of the solution, ensuring smooth progress through subsequent project phases.

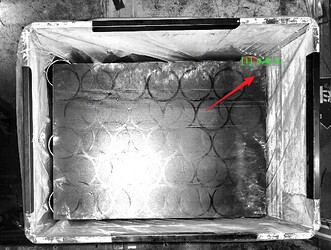

Reflective inner walls of the bin

Issue: The inner walls of the bin are reflective, resulting in poor point cloud images of the objects around the inner walls. The vision recognition will be affected.

Solution:

- Apply frosted treatment to the bin wall or cover the inner wall of the bin with non-reflective material.

- For how to adjust the mounting method of the camera, please refer to Optimize defective point clouds: Minimize multipath reflections in bins (reflective bin walls).

- Add isolation strips around the partition to ensure that the rings will not come close to the bin walls, as shown in the figure below.

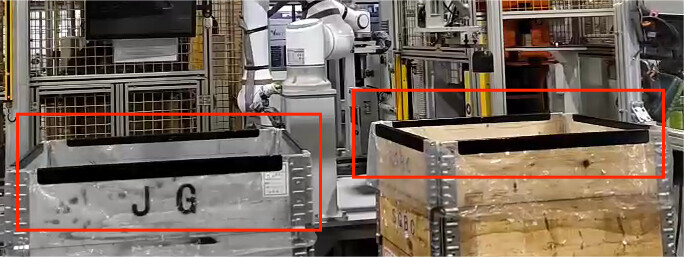

Objects obscured by plastic film

Issue: The objects are obscured by the plastic film inside the bin (as shown in the figure below), resulting in incomplete object point cloud data after the camera captures images. This issue becomes especially pronounced for the objects at the bottom of the bin, as they may be completely obscured by the loose plastic film, significantly affecting the results of capturing images and picking.

Solution:

- Moving the plastic film manually before loading can fundamentally solve this issue.

- Add U-shaped channels, as shown in the figure below. Add U-shaped channels manually to fix the plastic film before the camera captures images.

Small partitions

Issue: The partitions are small and cannot completely cover the next layer objects, causing the camera to mistakenly match the next layer objects as the current layer objects to be picked after it captures images.

Solution: Use larger partitions to completely cover the next layer objects. You can also adjust the matching strategy in the software. By setting a proper point cloud matching threshold, you can filter out the point cloud data of the objects below the partition.

Insufficient stability and low rigidity of partitions

Issue: Insufficient stability and low rigidity of partitions easily lead to warping and bending during use, as well as extrusion and erosion after being immersed in oil, which brings challenges to picking the partitions.

Solution: Select the partitions with sufficient stability and high rigidity in the early stage of the project and conduct regular maintenance in later use.

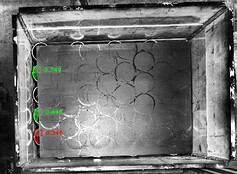

Imprints on partition

Issue: The imprints on the partition are mainly caused by the following two situations:

- The partition is made of soft material and gets crushed after long-term extrusion from objects. For example, there are concave imprints similar to the contact surface of the objects on the partition.

- If the bottom surface of the object is coated with anti-rust oil, an imprint similar to the object’s bottom surface contour may be formed on the partition.

The camera will capture images of the above two situations and generate corresponding point cloud data. Therefore, the imprints are mistakenly recognized as the objects of the current layer.

Solution:

- Select partitions made of harder materials and regularly clean those with heavier oil stains during use.

- During testing, only get the point clouds within the rings or use the counting method to avoid the effects of the imprints on the partition.

Reflective partitions

Issue: The partition is smooth on the surface and highly reflective, which affects the quality of object point clouds. In addition, the point cloud of the partition has poor quality and the accurate picking pose cannot be output.

Solution:

- Select partitions made of non-reflective materials or apply special treatment (for example, frosting) on the surface of the partitions to ensure that they are not reflective.

- If the point cloud loss of the partition is severe, you can use a sensor or calculate the layers of objects to assist in determining the picking pose of the partition.

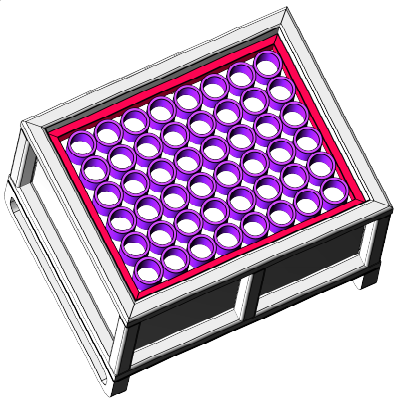

Small gap between copying pallet and object

Issue: If there are only a few feature points on the metal ring, some point clouds of the copying pallet will be mistakenly recognized as the object point clouds. In addition, if the gap between the copying pallet and the object is too small, it is easy to inadvertently move the partition when the robot picks the object, which causes the other objects on the partition to be moved together.

Solution:

- You need to deploy deep learning and iterate on the deep learning model of the empty copying pallet several times. A proper copying pallet design also helps to avoid mistake recognition.

- You can properly enlarge the gap between the object and the copying pallet to avoid moving the partition inadvertently when the robot picks the object.