Introduction

Target readers: solution engineers, layout planning engineers, mechanical design engineers, mechanism design engineers

Overview: This article focuses on projects related to neatly arranged cylindrical rods. It provides detailed insights into issues regarding the rods, bins, and partitions, along with corresponding strategies. This content guides the overall project design and smooth progress in the later stages.

1. Light Reflection from Bin Wall

Specific issue: Glare on the bin wall results in poor imaging of the point cloud near the bin wall, affecting vision recognition.

Strategy: Apply frosted treatment to the bin wall or cover the inner wall of the bin with non-reflective material.

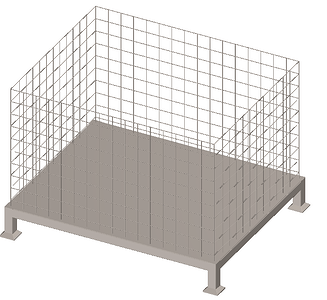

2. Insufficient Stability and Low Rigidity of Bin Side Walls

Specific Issue: The side walls of the bin are welded with iron mesh. The following problems are encountered during actual usage:

- Prolonged use causes severe deformation of the bin side walls (either inward or outward), leading to significant difficulties in picking.

- Sparse point cloud on the upper edge of the bin side walls makes it challenging to accurately identify the actual position of the bin when dynamically updating the bin.

Strategy: Use square steel or other high-strength materials for the bin side walls and regularly inspect and maintain them during the usage process.

3. Presence of Covering Material between Bin and Workpieces

Specific issue: Plastic film around the bin obstructs the workpieces.

Strategy: Remove the film manually before loading.

4. Adhesion of Oil Stains and Iron Filings on Workpiece Surface

Specific issue: The incoming workpieces have significant oil stains and iron filings on the surface, making it easy for the magnetic gripper to lose grip.

Strategies:

- Use claw grippers or alternative handling methods.

- If using magnetic grippers, clean the surface of the rods to remove iron filings and oil stains.

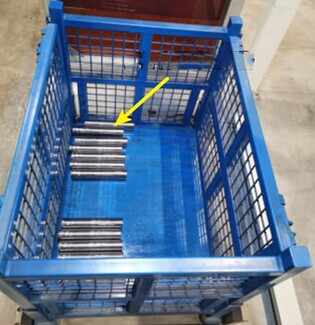

5. Mesh Bin Walls

Specific issue: The mesh bin walls have a larger cross-sectional area than the workpieces, making it easy for the workpieces to protrude outside the bin, making them unreachable.

Strategy: Seal mesh bin walls with cover plates.

6. Partitions of Transparent Material

Specific Issue: The partitions are made of highly transparent material, allowing the camera to easily recognize the lower-level workpieces through the partitions.

Strategy: Use non-transparent or frosted partitions.

7. Insufficient Stability and Low Rigidity of Partitions

Specific issue: Insufficient stability and low rigidity of partitions leads to the following problems during actual usage:

- The partitions are prone to deformation, causing suction cups unable to lift them.

- Issues arise with dropping after grabbing the partitions.

Strategy: Use high-strength materials or add reinforcement bars to the partition to enhance the strength of the partitions.

8. Smooth Bottom of the Bin

Specific issue: The bottom of the bin is very smooth, causing the rods to easily shift position within the bin. After the camera captures the rods and the calculation of poses is done, the actual positions of the rods may change due to rolling, making it difficult for the robot to pick accurately.

Strategy: Place high-friction pads or other materials that can serve the same function on the bottom surface of the bin.