-

Analysis principles of measuring projects:

Workpieces have tolerances, generally requiring visual accuracy of 1/10 to 1/5 of the tolerance zone. For example, when producing a workpiece with a length of 50mm, a tolerance of ±0.5mm is considered acceptable. Therefore, the accuracy/error requirement for the visual system is 0.1mm = ±0.05mm. -

Accuracy analysis of the inspection system

(1) Comprehensive accuracy

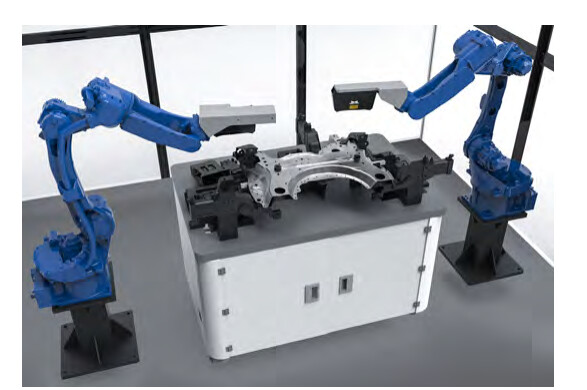

Determine whether the system needs to be integrated with a robot, such as position detection. If so, the robot error should be added to the vision system error. Note: This is not a simple additive relationship.

The LNX laser profiler needs to be triggered in conjunction with the encoder of the linear motion mechanism, so its Y-axis accuracy will be affected by the encoder’s accuracy.

(2) Vision system

The accuracy of the vision system consists of hardware accuracy and software/algorithm accuracy . In practical projects, the software algorithm accuracy can be ignored and considered equal to the camera’s intrinsic accuracy. For example, for UHP, the accuracy is within 30μm.