Example 1: Loading battery cells

Situation:

- The height of the stacks is 1,400 mm. Based on specific needs, we choose LSR L here.

- Since the loading items, battery cells, come in different sizes, the parameters of the grippers depend on the sizes of the battery cells. Additionally, the accuracy should be within 1 mm. Therefore, a single LSR L camera will not suffice.

Solutions:

- First, use a LSR L camera for crude positioning.

- Second, use a PRO S camera for high accuracy positioning.

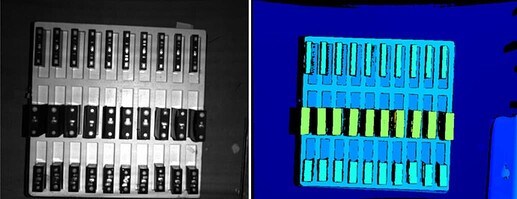

Below are results of crude positioning (LSR L):

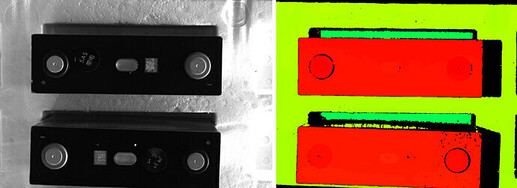

Below are results of high accuracy positioning (PRO S):

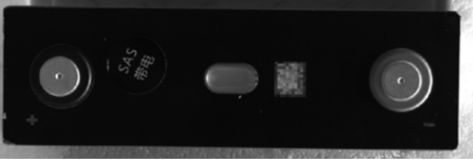

Calibrations of the above two cameras:

- LSR L (large FoVs): ETH.

- PRO S (small FoVs; high accuracy): EIH.

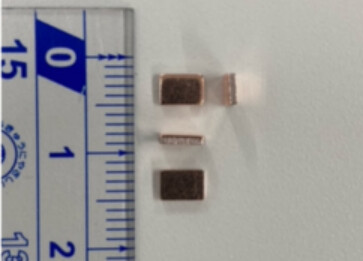

Example 2: For small workpieces with thickness values between 1 mm to 3 mm, how to achieve high accuracy positioning with PRO S 1000 cameras? Or how to choose cameras for such workpieces?

- Problem: Defective point clouds.

- Analysis: Some workpieces are small and thin. Therefore, to capture complete images and point clouds of these workpieces, it is necessary for each of them in the picture to have an adequate number of pixels.

- The crux: Move the camera closer to the workpiece.

- Minimum number of pixels (each workpiece; optical power): 10 (20–30 is preferable).

- Solution:

- Properly lower the camera position (within the depth of field).

- Choose a camera with the same focal length but higher resolution. In this case, a UHP-140 will suffice.